ANY INDUSTRY

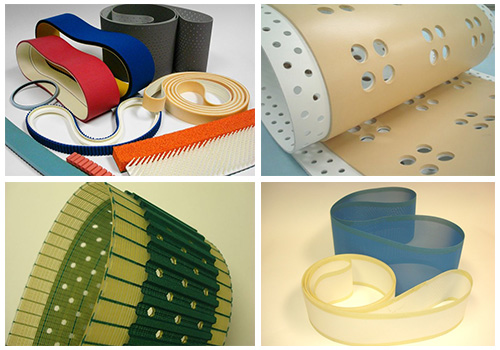

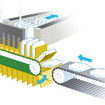

BELTING PRODUCTS & SERVICES

WE DESIGN SOLUTIONS

F.N. Sheppard’s belting services have the ability to engineer, manufacture, and install any belt product/hardware to keep your business producing. We have the capabilities to consult with your designers and engineers so that you’ll know the job is done right the first time.

APPLICATIONS

You have an APPLICATION, we have the BELTING SERVICES

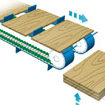

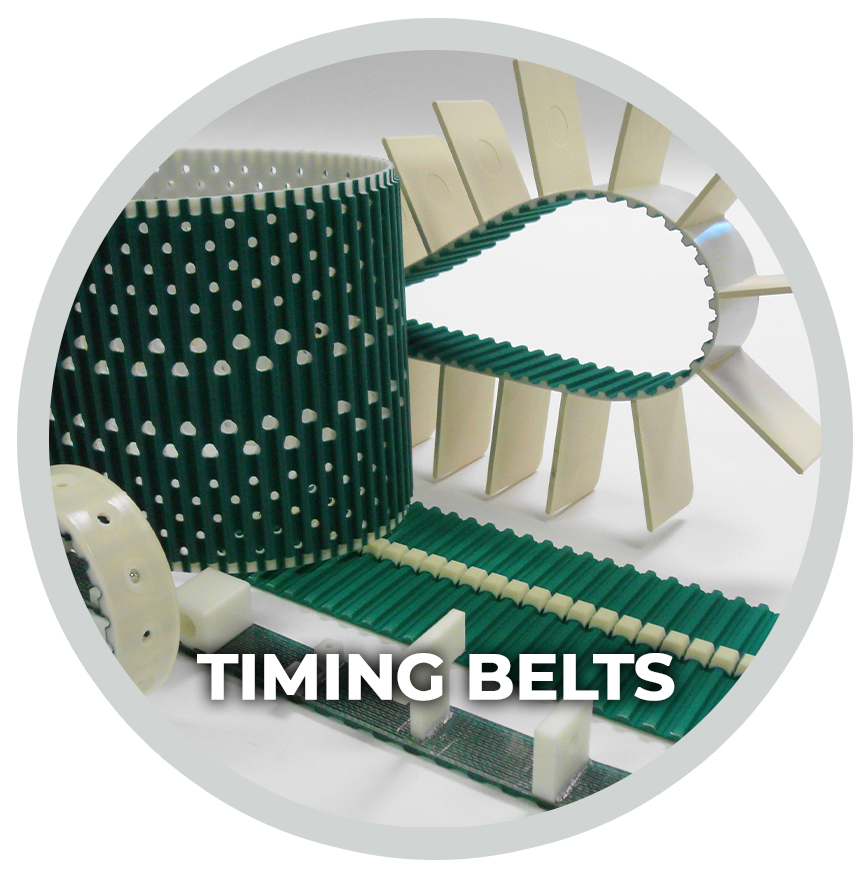

Synchronous Stacking Conveyor

- Urethane Timing Belt

- Self-Tracking Guide

- Strong Profiles

WE OFFER

Unlimited BELT Designs, GLOBAL coverage

INTERNATIONAL PRODUCTS & SERVICES

From understanding your belting needs and providing consultation to engineering and complete production, FN Sheppard & Co. provides belting services and products to customer around the globe.

NATIONAL PRODUCTS & SERVICES

From belt engineering and complete belt production to on-site consultation and belt splicing/installation, the belting possibilities are endless. FN Sheppard, Co. has the ability to provide these belting services throughout the U.S.

CONTACT US

Let us HELP you to find a SOLUTION that meets your needs.

Contact us today by filling out the form on the right or feel free to contact us via email or phone.

- (800) 733 – 5773

- beltinfo@fnsheppard.com