Globax news

Blog

F.N. Sheppard: Timing Belts Unveiled – Working, Materials, and Applications

Timing belts, seemingly simple yet remarkably efficient, constitute a fundamental machine element meticulously designed to synchronize motion.

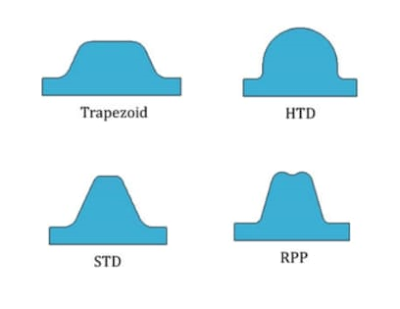

The Working of Timing Belts Timing belts are distinguished by their toothed structure, a feature that sets them apart in the realm of power transmission. These teeth mesh seamlessly with the corresponding teeth on a belt pulley, akin to the precise engagement of gears. This harmonious interplay ensures that rotational motion from one pulley is faithfully and accurately transferred to the next. Timing belts, in essence, conquer the age-old challenge of slip encountered by flat or V belts, enabling the conveyance of power and motion with unparalleled precision and synchrony.

Materials of Timing Belts While rubber stands as the most prevalent choice, the material selection for a timing belt is a multifaceted decision, contingent upon a spectrum of requirements such as wear resistance, tensile strength, fatigue resistance, and creep behavior. This choice hinges significantly on the unique application that the timing belt will serve. It introduces the three primary materials employed in timing belt manufacturing:

- Urethane: Renowned for its minimal elongation rate and exceptional tensile load capacity, urethane excels in handling high temperatures while maintaining dimensional precision.

- Polyurethane: A composite of urethane and polyester, polyurethane timing belts are the go-to for applications subjected to substantial shock loads. This material amalgamation enhances strength, durability, and flexibility, rendering it ideal for intermediate shock load scenarios.

- Neoprene Fiberglass: Characterized by their extended shelf life and resistance to UV radiation, neoprene fiberglass timing belts thrive in corrosive and chemically challenging environments, proving their mettle in diverse settings.

Applications, Advantages, and Disadvantages Our comprehensive guide extends to the myriad applications of timing belts across industries, elucidating their pivotal role in various mechanical systems. Additionally, we explore the advantages they offer, such as precise motion transfer and synchronous operation. Conversely, we dissect the disadvantages, acknowledging the nuanced considerations that engineers must weigh in their pursuit of optimal power transmission solutions.

For more information on F.N. Sheppard’s expertise and offerings, click here.

Photo and article with all rights reserved, courtesy of green-mechanic.com