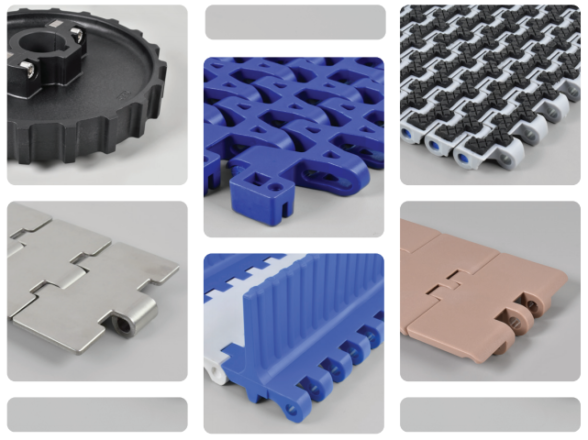

Globax portfolio

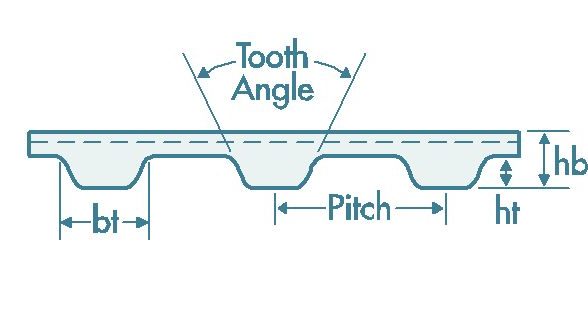

Timing Pulleys & Drive Design Type

Details

- Category: Timing Hardware, Timing Pulleys

- Timing Tooth Pitch Inch & Metric Sizes

- Construction Steel, Stainless, Plastics

- Standard & Custom Manufactured to Your Specs.

Description

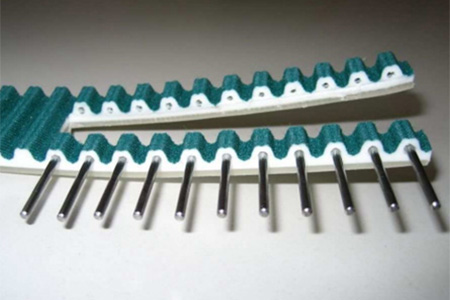

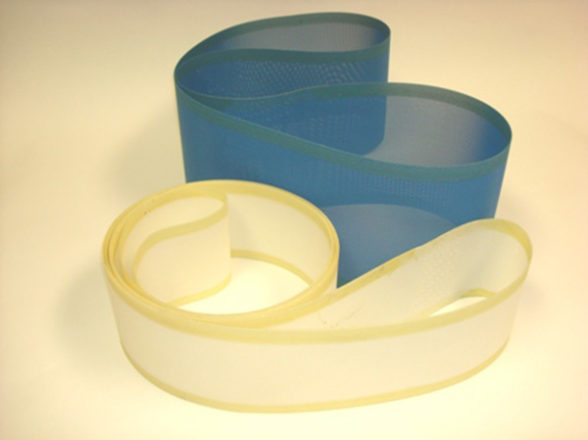

Here’s another way F. N. Sheppard can help solve your production problems – with a wide array of pulleys and hardware, including standard and custom sizes. Just as having the right belts are important, it’s just as essential to have the right pulleys and hardware.

| Pulleys |

Pulley Bar Stock Bored Sizes Custom Sizes, Machining and Treating – FDA/USDA Aluminum, Steel, Cast Iron, Stainless Steel, Delrin – Depending on pitch and size |

| Additional Processes |

|

| Additional Hardware |

|

| Inch Sizes | MXL /0.080″, XL /0.200″, L /0.375″, H /0.500″, XH /0.875″ |

| Metric Sizes | T2.5, T5, T10, T20, AT5, AT10, AT20 |

| HTD® Sizes | 3M, 5M, 8M, 14M |

| No. of Teeth | 10 – 72 |

| Inch Pitch (in) | XL (0.200”) L (0.375”) H (0.500”) XH (0.875”) |

| Metric Pitch (mm) | T5 – T20 / AT5 – AT20 |

| PD (in) | 0.64 – 20.05 |

| OD (in) | 0.62 – 114.60 |

| PD (mm) | 15.9 – 458.4 |

| OD (mm) | 15.1 – 455.5 |

TO PLACE AN ORDER PLEASE CONTACT OUR EXPERIENCED AND PROFESSIONAL CUSTOMER SERVICE TEAM:

- PHONE: 1-866-672-6339

- EMAIL: beltinfo@fnsheppard.com

Wish to speak with someone right away? Simply call and speak to one of our knowledgeable F.N. Sheppard experts. They will be able to begin engineering a belt that suits your needs quickly and professionally.

Note

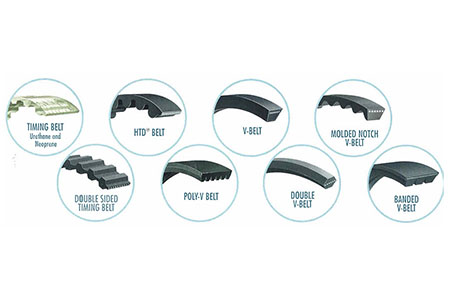

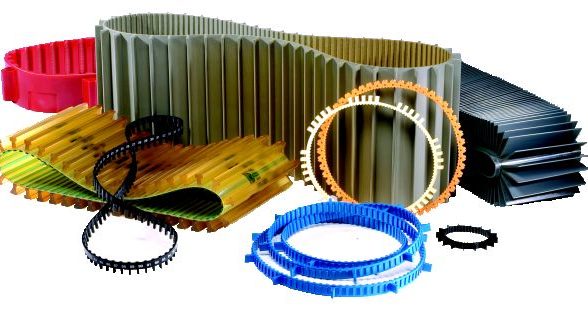

Many other styles and types are also available

This chart is a reference for pulley diameters (outside and pitch) for a given number of teeth and a given tooth profile.

Pitch Diameter – Pitch x number of teeth / 3.1416