Globax portfolio

Non-stick and Release Coatings

Details

- Category: Other Products, Specialty Release Coatings

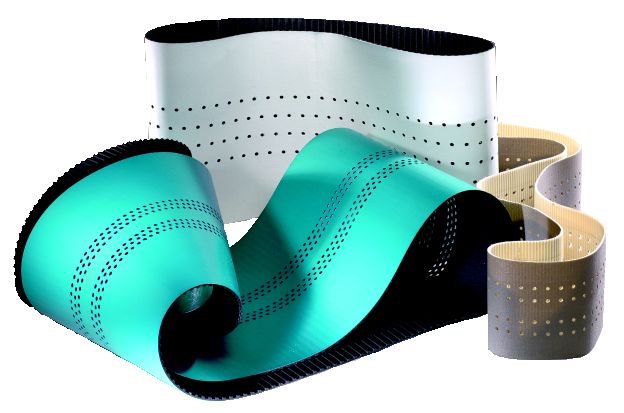

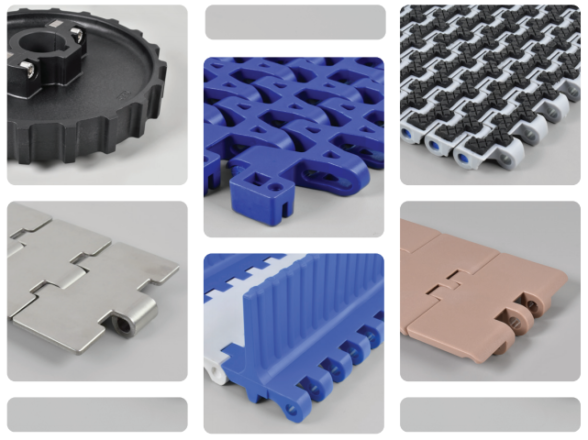

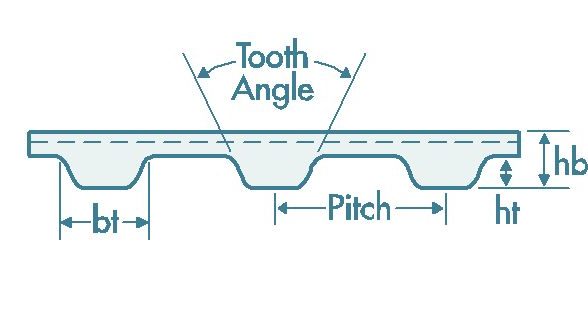

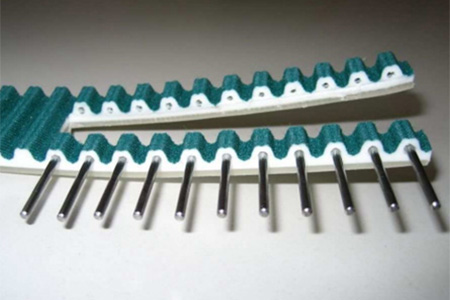

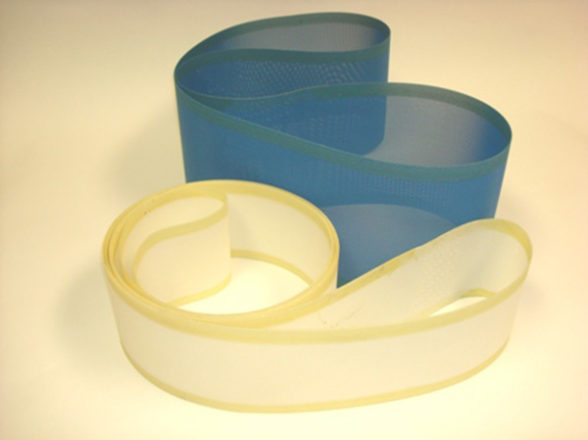

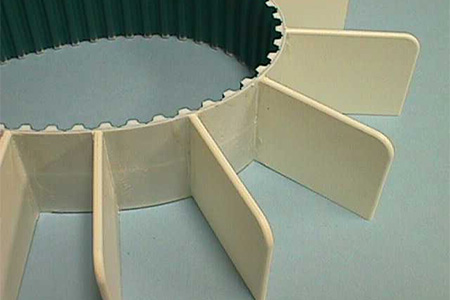

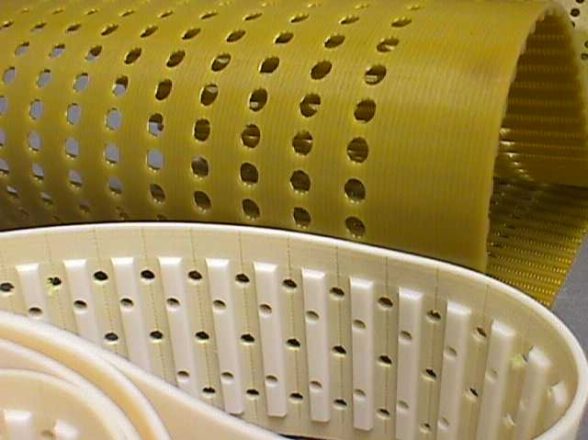

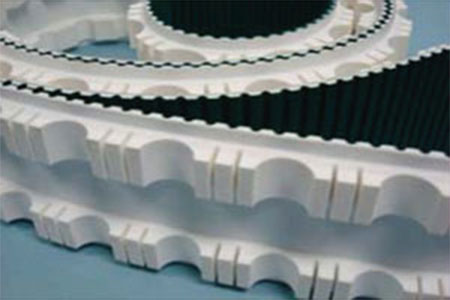

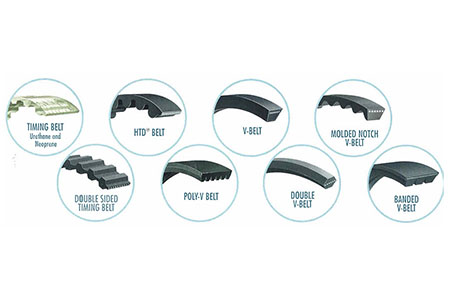

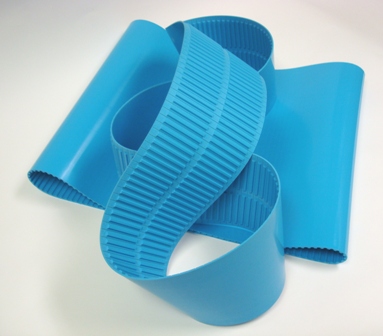

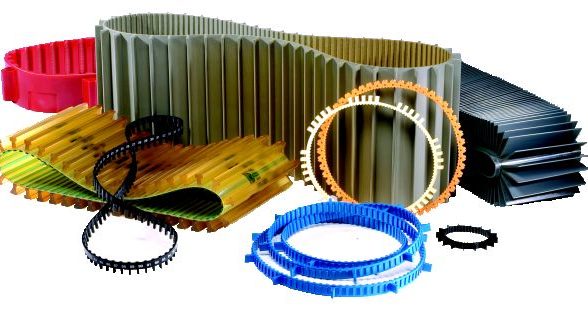

- Timing & Conveyor Belts, Rollers etc.

- Glue Release

- Improve or Reduce Coefficient of Friction

- FDA Coatings

Description

If you experience problems with glue, labels, or other material sticking to your belt surface, then we can apply a variety of silicone or urethane release coatings to eliminate the problem. You may just want to alter the friction properties, color or hygiene characteristics of a standard belt.

| Non-Stick Coating | Many synchronized conveying processes may include some form of product folding, gluing, laminating, or labeling. We produce several variations of silicone and urethane release coatings that are applied to the belt surface to help eliminate the possibility of belt contamination. Typically, vacuum conveyors are used with perforated timing belts. The vacuum, combined with our coating, can create the desired positive control of the product. The coating process allows us the flexibility of coating many different substrates, including urethane and neoprene timing belts, regardless of the belt width or length. |

| Coating Characteristics What They Can Offer |

|

| Belt Surfaces: All Types |

Belt top side or conveying surface Belt bottom side of belt which comes in contact with slider bed Belt fabrics (top or bottom) Timing Belt teeth |

| Other Materials |

|

TO PLACE AN ORDER PLEASE CONTACT OUR EXPERIENCED AND PROFESSIONAL CUSTOMER SERVICE TEAM:

- PHONE: 1-866-672-6339

- EMAIL: beltinfo@fnsheppard.com

Wish to speak with someone right away? Simply call and speak to one of our knowledgeable F.N. Sheppard experts. They will be able to begin engineering a belt that suits your needs quickly and professionally.