From custom designing and engineering, to manufacturing and supplying our Timing Belts around the globe.

F.N. Sheppard & Co. has the solution to your Timing Belt needs.

Anaconda is a patented new product created by F.N. Sheppard & Co. for high-speed conveying applications where precision tracking is essential.

Anaconda is both a synchronous belt and a conveyor belt in one!

F.N. Sheppard has the ability to create any style, type, and design for practically any belting application you need.

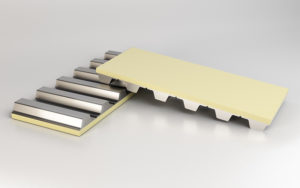

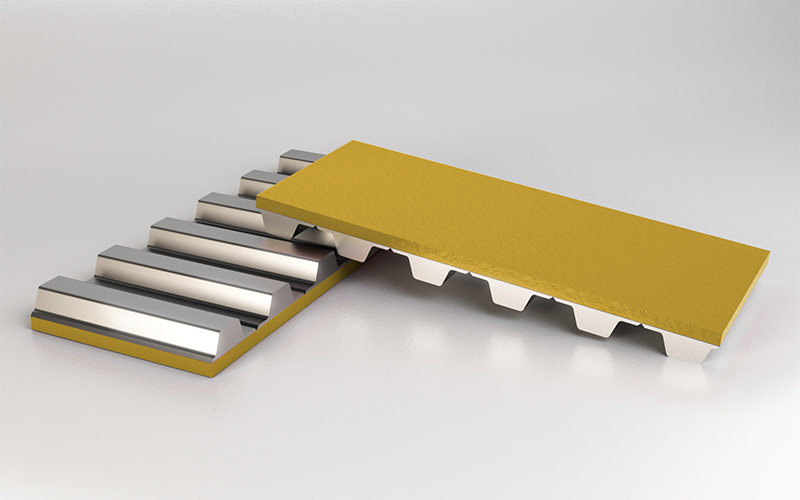

With molded endless High Temp & Silicone Belts from F.N. Sheppard & Co., there are no seams or splices.

These belts have the ability to handle temperatures upwards of 500° F.

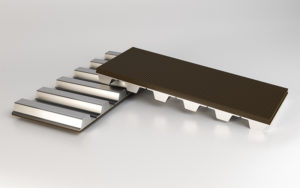

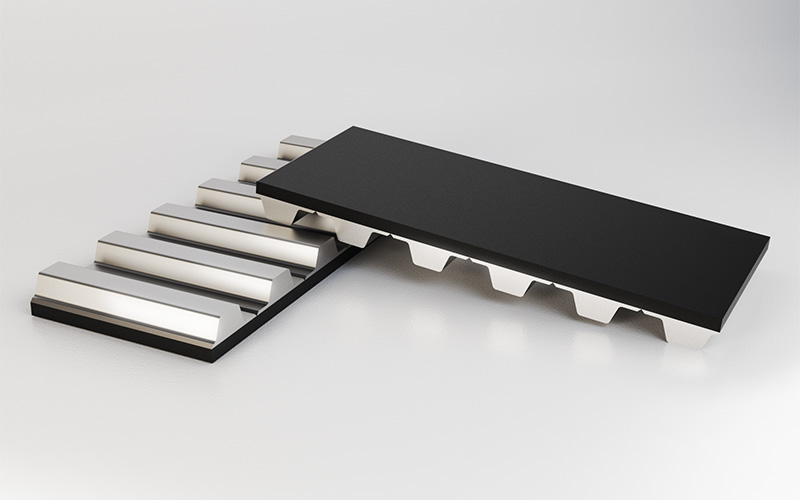

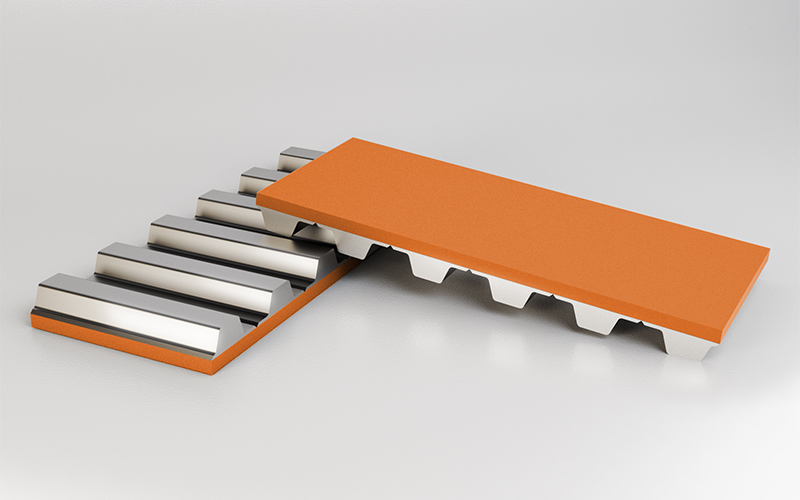

Benefits of Neoprene Timing Belts range great resistance to chemicals and harsh temperatures to great strength and durability under some of the toughest of conditions. Looking for a synthetic belting material that has it all? Neoprene Timing Belts may be what you're looking for.

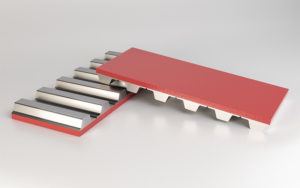

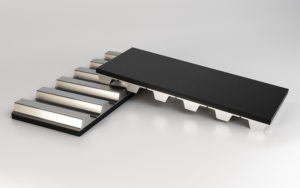

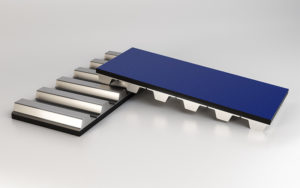

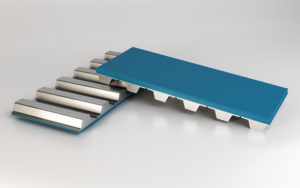

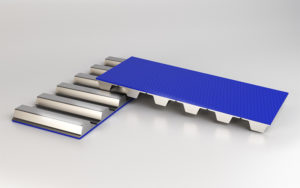

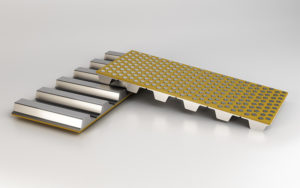

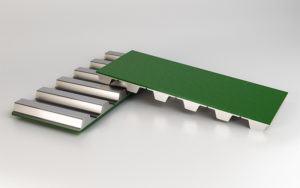

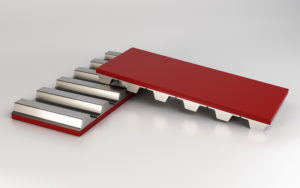

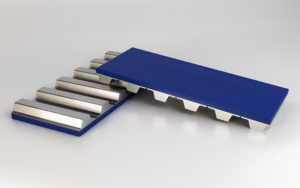

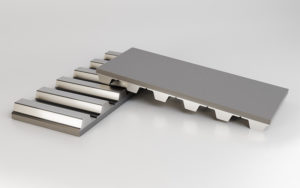

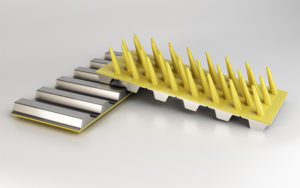

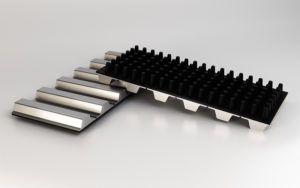

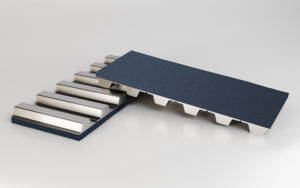

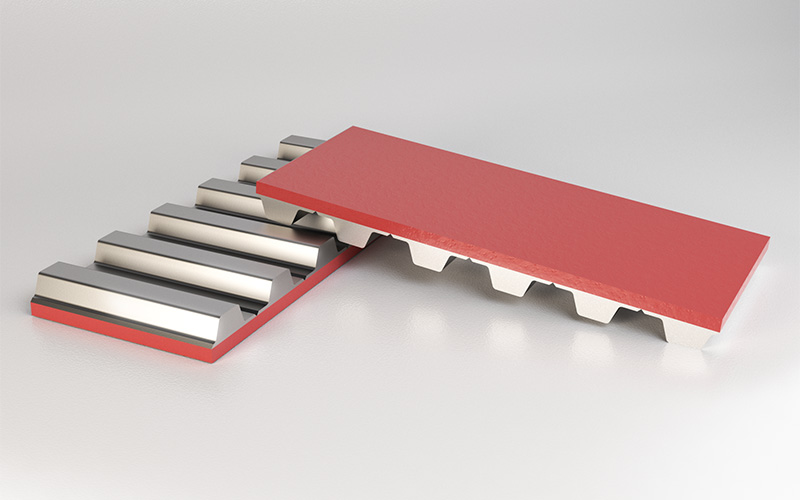

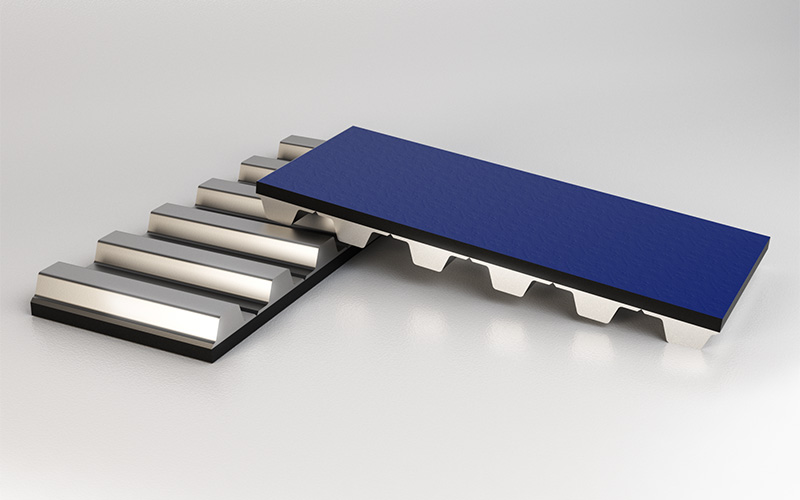

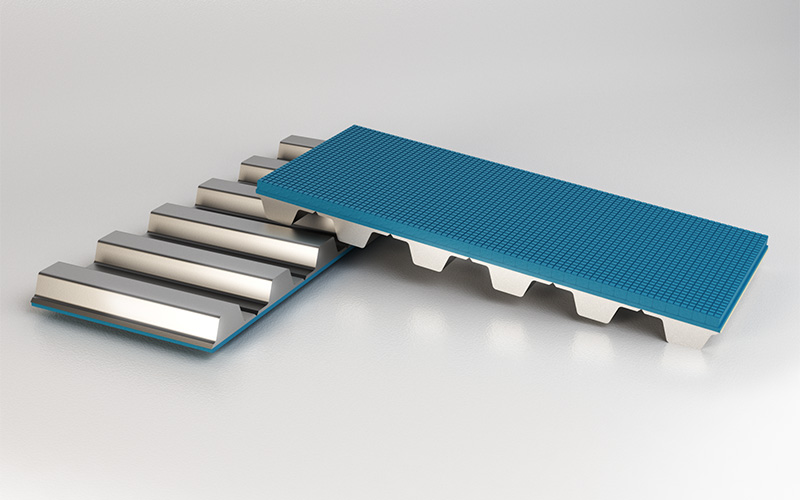

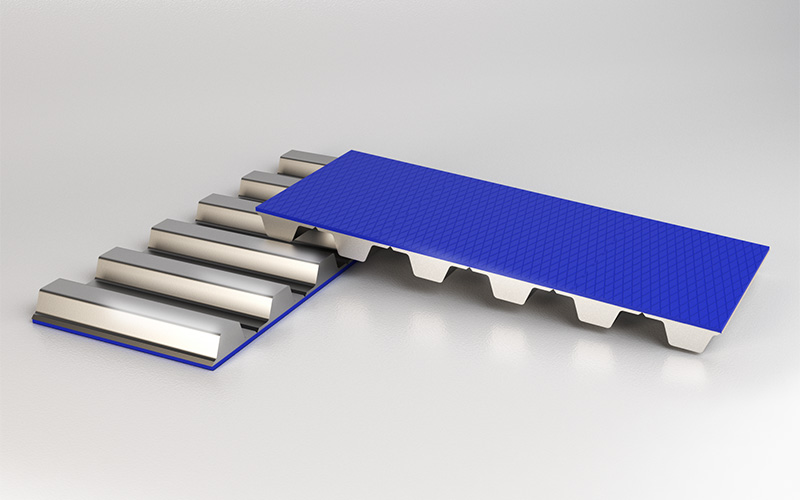

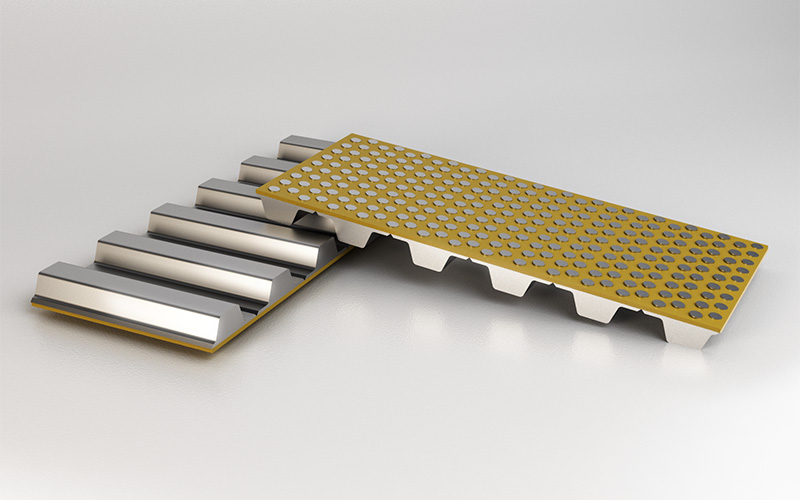

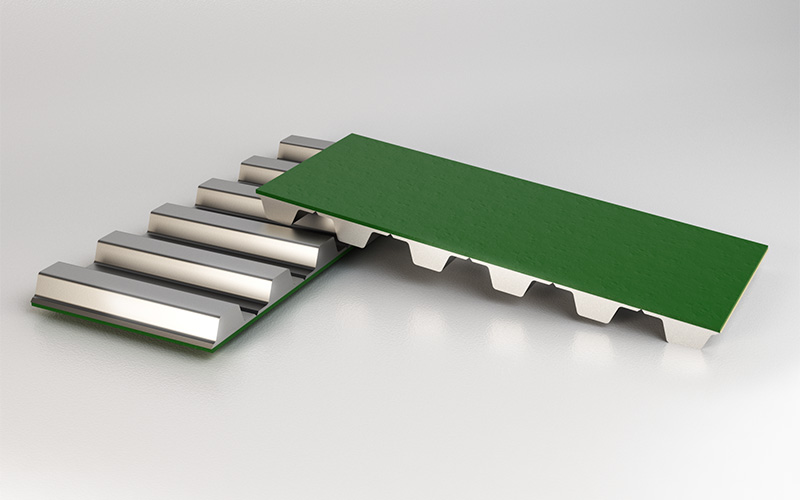

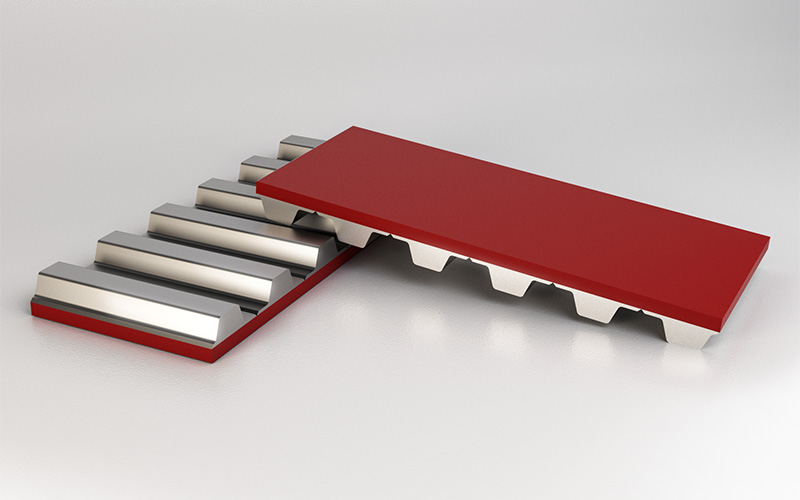

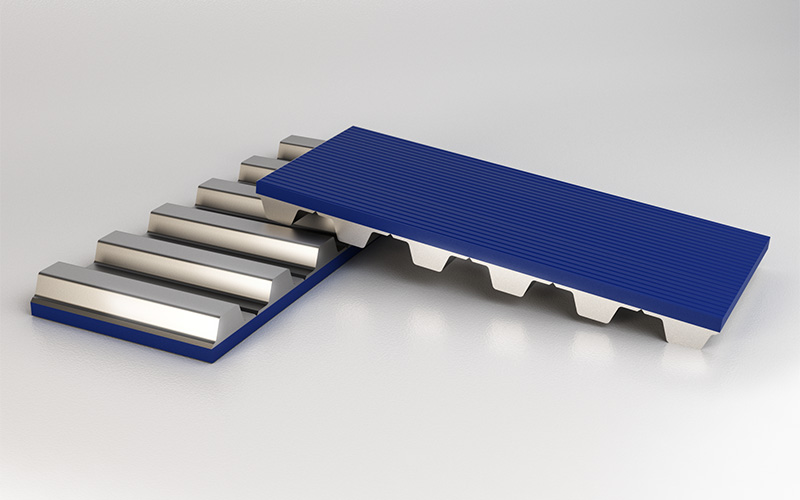

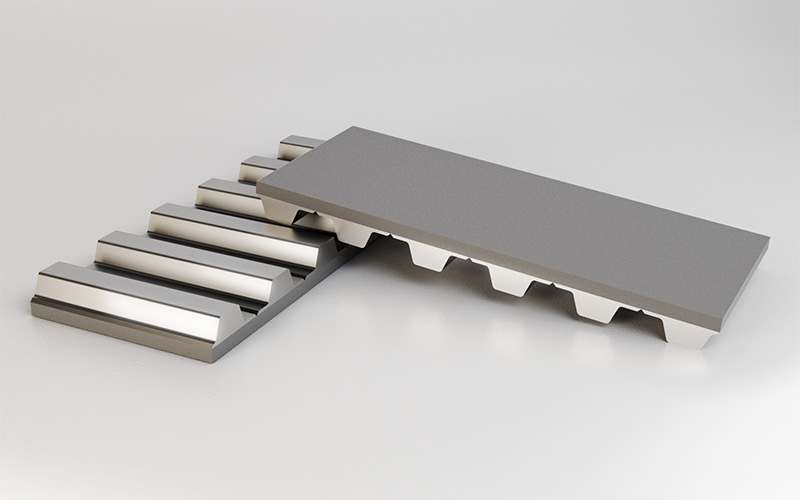

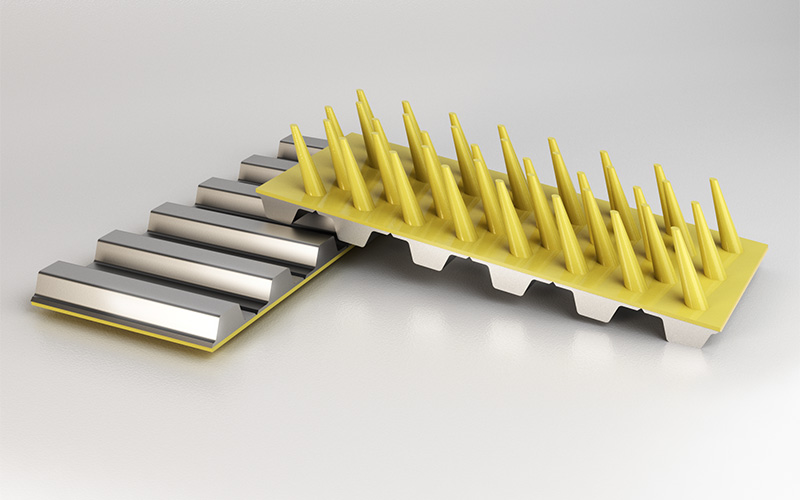

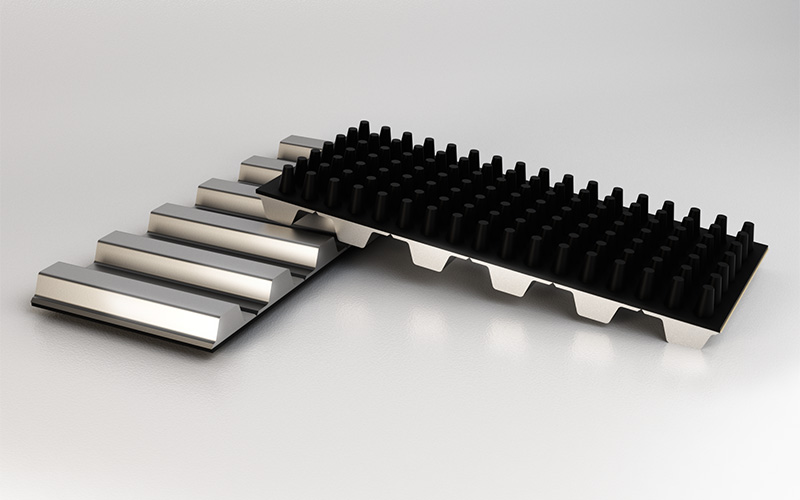

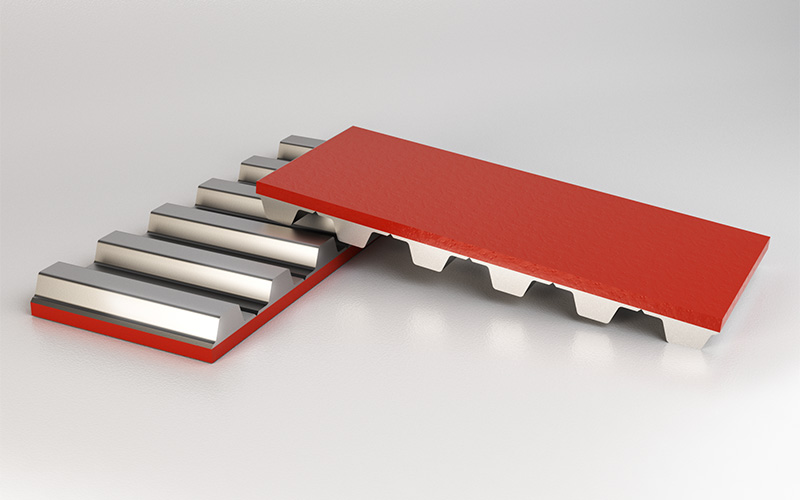

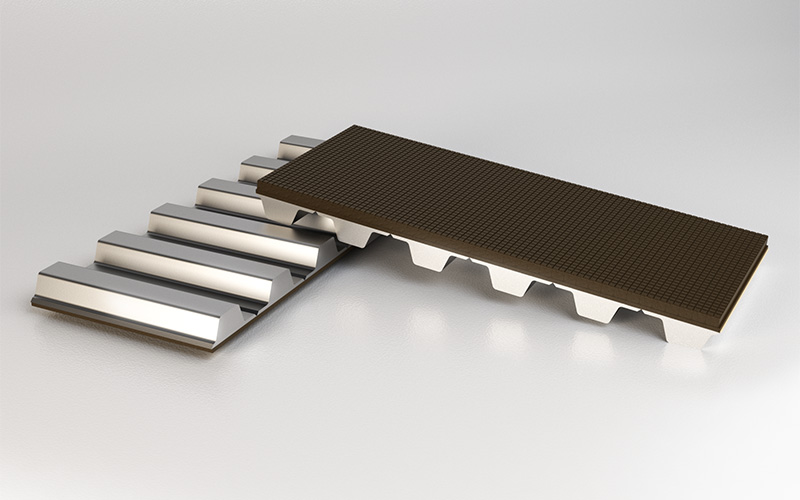

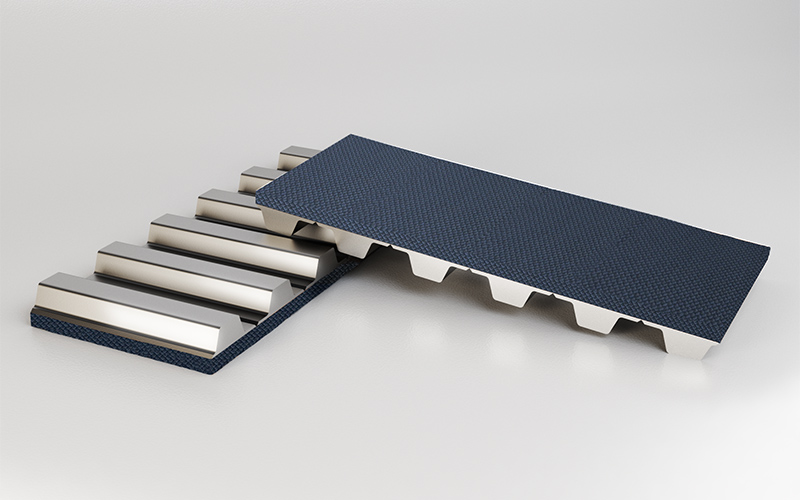

Profiled/Cleated timing belts can provide exceptionally accurate synchronized conveying of products. Profiles are commonly referred to as lugs, cleats, pockets and attachments. Profiles are transverse raised sections on the outer surface of a belt used to hold, stabilize, position or transport a product.

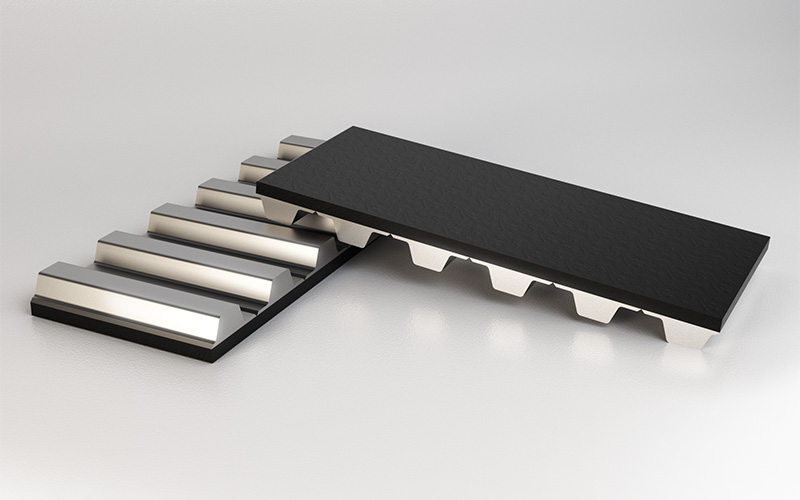

F.N. Sheppard & Co. takes pride in its ability to design, engineer, fabricate, and produce any Timing Belt solution you may need. False Tooth Belts, Mechanical Pin Splice Belts, Vacuum Perforated Belts, and Pocket Belts are just the some of the possibilities.

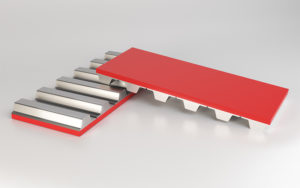

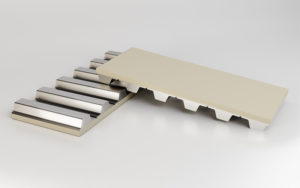

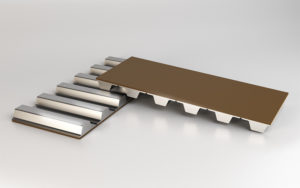

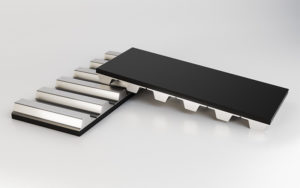

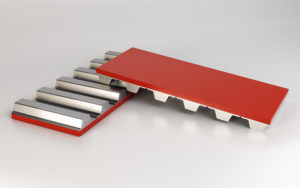

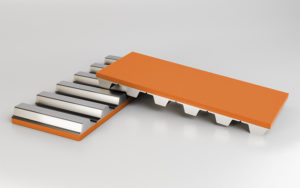

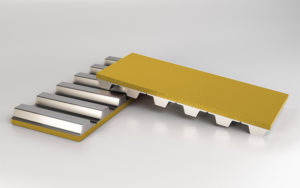

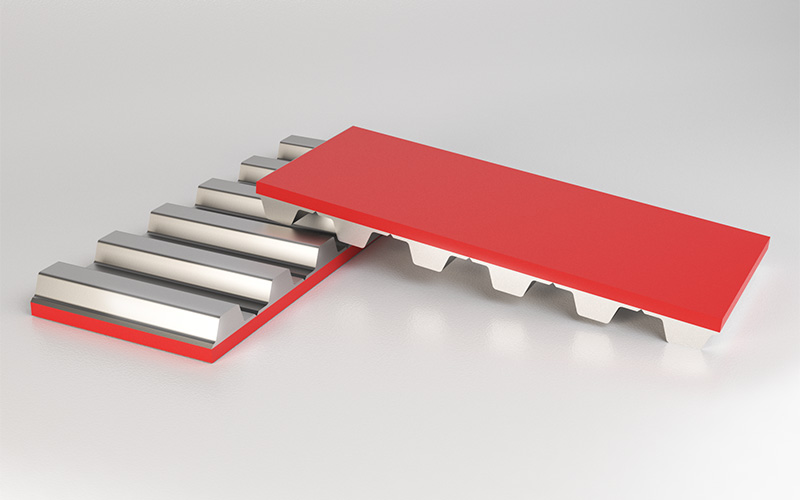

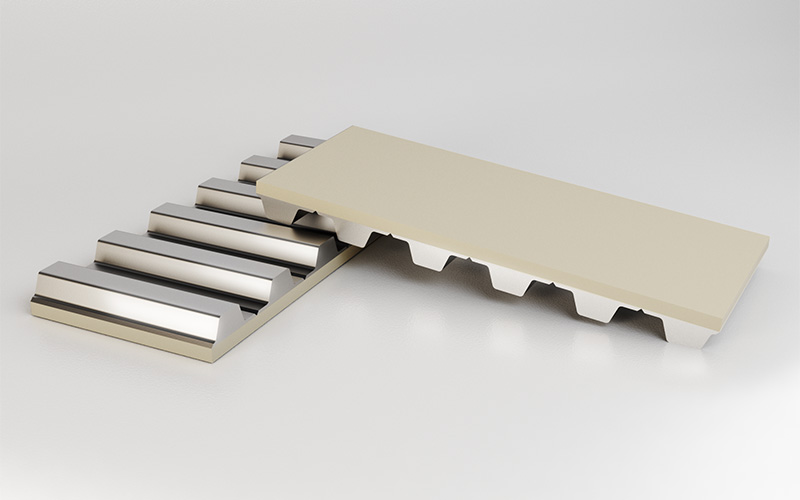

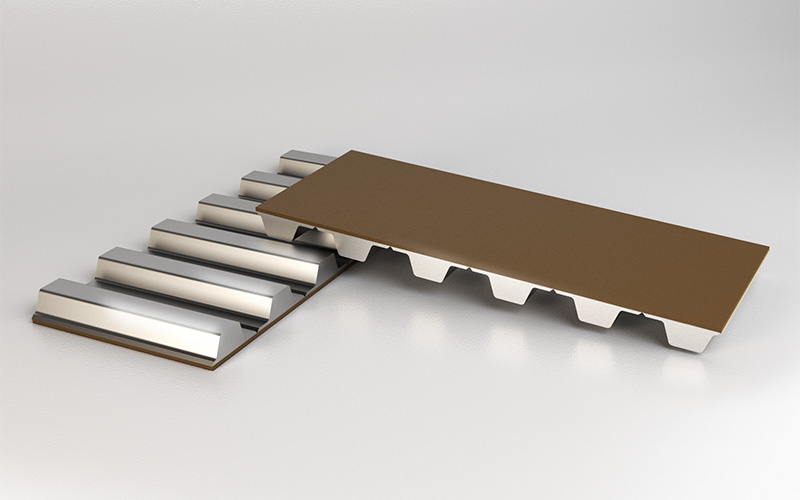

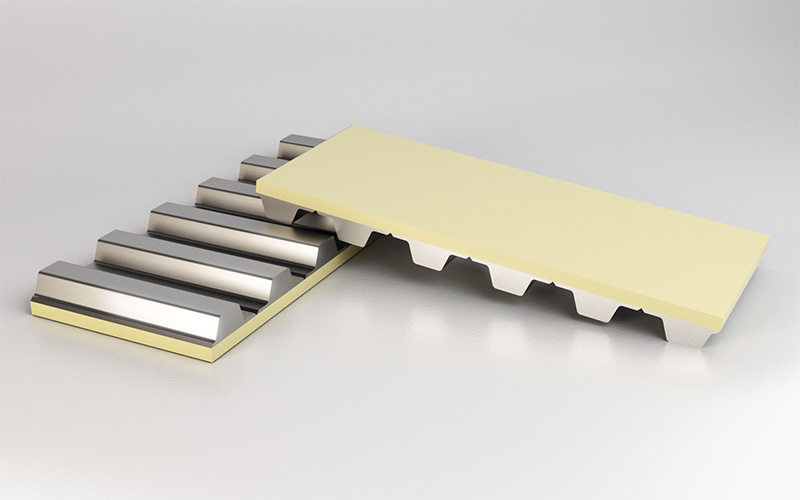

Urethane Timing Belts offers extremely good abrasion resistance. Low wear means that the belts will be very clean running, with no accumulation of debris. Urethane teeth are much harder than traditional neoprene teeth, which contributes to the belts overall stiffness.