Globax news

Blog

All About Slat Conveyors – Types, Design, and Uses

New to slat conveyors? Here is everything you need to know.

According to Thomas Net:

“How would you move a dozen 500+ lb engine blocks across a factory within a workday?

“When materials must move between two stations, designers often implement material handling equipment to help out. These machines reduce the need for manual labor and increase the pace of progress in any application they are a part of. The most popular version of these systems is the conveyor, which is a machine that allows for the smooth transfer of product using belts, buckets, augers, and more. To get an idea of how many different types of conveyors there are, read our article on understanding conveyor systems, but know there are a paralyzing amount of options. This article will take a closer look at slat conveyors, their functionality, types, and applications, to help understand what is available. By learning about this specific conveyor, buyers can decide slat conveyors will work for their needs, or if another conveyor system is more suitable.

What are slat conveyors?

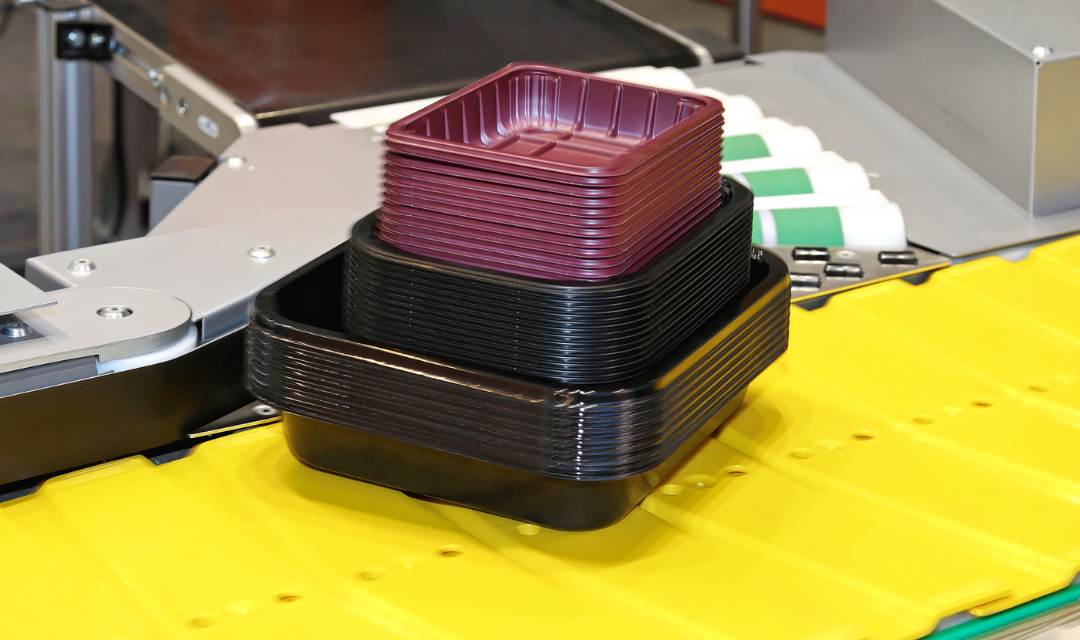

“Slat conveyors are a type of conveying technology that utilizes a chain-driven loop of slats to move product from one of its ends to another. The chain is driven by a motor, which causes it to cycle just as belt conveyors do. The main difference is that, instead of a rubber belt, this conveyor type uses slats connected to a chain, not dissimilar from vehicle treads. The result is a conveyor that provides a rigid, flat surface for every item on the conveyor, which is ideal for many kinds of products that cannot be used on rollers or belts due to their irregular shape. These slats are typically made of engineering plastic or metal, which allows slat conveyors to function in hazardous, high weight, and high-temperature environments. Another major advantage is that the slats can be built with unique shapes (such as in Figure 1), giving them more use-cases than most conveyors. They come in a range of speeds and widths and have optional side railings to guide materials through the conveyor system, if desired.

“The slat conveyor is most useful for heavy products that would normally damage most conveyors, as well as for hot or dangerous items. They control the orientation of an object and are widely used in manufacturing plants as assembly line conveyors. Typical slat conveyors only work in straight runs, but smaller, more flexible slat chains have been made to allow for curved slat conveyors which find many uses in the food and bottle manufacturing industries (though these tend to fall under the umbrella of chain conveyors, as they are thin and chain-like). They work great in harsh environments and can get wet or oily without much risk of damage and are only held back by their inability to accumulate materials on their surface (though, special slat conveyors exist to meet these needs in specific applications). Slat conveyors are also most useful when horizontal or slightly inclined, but again, exceptions exist.

Types of slat conveyors

“Slat conveyors are classified more so on application and motor size, so there are many, many kinds of slat conveyors available for purchase. This article will provide some examples of different slat conveyor types to not only show the variety of options, but also the most popular ones in use today.

Standard slat conveyors

“Standard slat conveyors are used throughout industry to transport small to medium-sized objects that require orientation control and no accumulation. They range in size and rating, but they are most often energy-efficient and can run at a faster speed than other slat conveyor types thanks to their smaller profile. Figure 2 shows a standard slat conveyor that has side frames to keep the product from falling off the conveyor, and these can be altered to allow for unloading/onloading, if needed. They work great if you need a straight conveyor capable of moving general items, or if workers must interact with smaller product for assembly.

Heavy-duty slat conveyors

“Heavy-duty slat conveyors are vital components of the automotive manufacturing market, as they are the heart and soul of assembly lines. They provide workspace, support, and transport of heavy, irregular materials with ease, and are rugged enough to work under such stress. Given the right drive, they can convey many thousands of pounds, albeit at speeds slower than smaller conveyors. They come in many arrangements but are generally integrated into the workspace (in Figure 3, for example, the slat conveyor is in a recessed portion of the floor and is known as a walk-on or walk-over conveyor) While expensive to both purchase and power, they are easy to maintain and are reliable machines, and find uses in heavy-duty applications that require toughness when conveying.

Apron conveyors

“Apron conveyors are specialized slat conveyors that implement interlinked slats with raised edges to create a sealed, moving trough. It provides a conveying surface that can move both solids and aggregates, and even semi-liquids such as concrete and slurry. They can be made leakproof and are rugged enough to transport hot or corrosive materials. They are often used in an incline to feed/discharge material from differing elevations, as their design is inherently self-containing. They find uses in concrete delivery, ironworks, tunnel construction, chemical and recycling industries, and more.

Specifications and selection criteria

“Since there are many choices of slat conveyors, consider the below specifications to help you find the right one. These will help give suppliers a better idea of your application and needs so that they can provide you with the best solution in their inventory. As always, this list is not exhaustive and only provides general specifications that will allow your supplier to point you in the right direction.

Product weight, dimensions, & required distance

“Define the weight and geometry of your product, as well as how far it must traverse. This way, your supplier will be able to determine the weight and length requirements of the slat conveyor, as well as find one with the right accessories for the material’s shape. This will also inform what motor should be used, as it must be powerful enough to efficiently convey the loaded capacity of your application. Make sure your supplier knows if the conveyor will be used on an incline as well, as inclines both change the drive requirements and conveyor type.

Slat material, supports, and speed

“What the slats are made of depends on what materials they will interact with; for example, plastic slats are good for general purpose conveying, but cannot be used in high-temperature environments. Conversely, if hot or oily items are being conveyed, stainless steel slats may be a better option. Detail any potential chemical or physical interactions and choose the right material to protect from these circumstances. If supports are needed to secure the items, also be sure to find slats that can cater to these needs with mounting options or specialized geometries. Finally, determine the speed of the conveyor, as this will affect both the slat type and what supports must be used. If speed or supports are not necessary for your application, then a more general-purpose slat conveyor may be your best option.

Control & special considerations

“Slat conveyors can work in continuous and in indexed modes, so determine what the desired behavior of the conveyor will be before consulting your supplier. There are many options that provide both constant and variable speed control, and there can be added electronic equipment that can be connected to larger control systems. Finally, ensure any application-specific requirements are given to your supplier; these could be environmental considerations, sanitation and sterile requirements, or any other important feature that the conveyor must meet. If these cannot be met by any available slat conveyors, consider another conveyor type.”