Globax portfolio

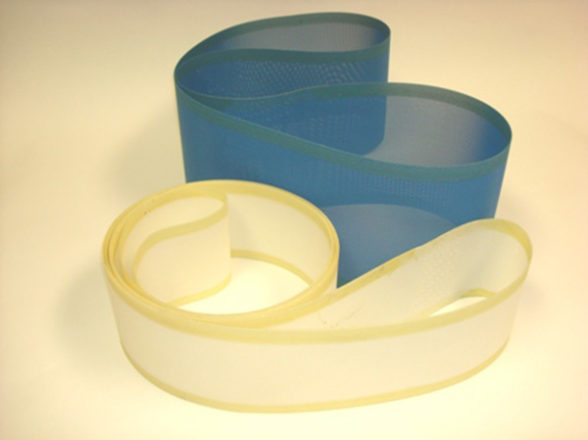

PTFE & Silicone Belts

Details

- Category: Conveyor Belts, PTFE & Silicone Belts

- Teflon & Silicone Fiberglass Belts, Fabrics, Tapes

- High Temperature Resistance & Excellent Release

- Wide Variety to Select From

Description

F. N. Sheppard also markets many special high performance flexible composite products. Many are used in packaging, food processing, electronics and chemical processing industries. Some products include; PTFE and silicone coated fiberglass fabrics, PTFE coated Kevlar® fabrics, PTFE coated tape and die-cut parts.

TO PLACE AN ORDER PLEASE CONTACT OUR EXPERIENCED AND PROFESSIONAL CUSTOMER SERVICE TEAM:

- PHONE: 1-866-672-6339

- EMAIL: beltinfo@fnsheppard.com

Wish to speak with someone right away? Simply call and speak to one of our knowledgeable F.N. Sheppard experts. They will be able to begin engineering a belt that suits your needs quickly and professionally.