Globax portfolio

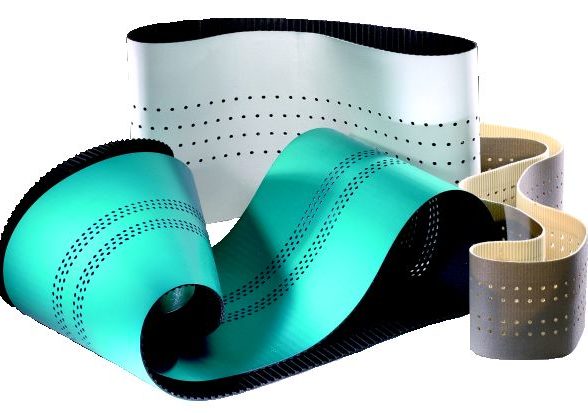

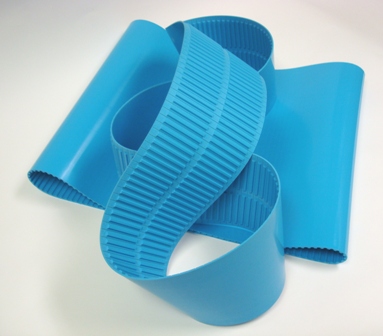

Welded Endless & Open Ended Urethane Timing Belts

Details

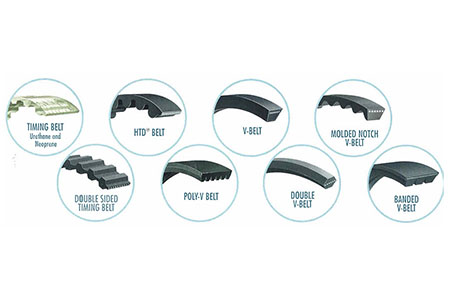

- Category: Timing Belts, Urethane Timing Belts

- Urethane Construction, Steel & Kevlar Reinforced

- Pitch Sizes: Inch & Metric

- Long Roll Lengths or Cut To Length Required

Description

- Description

- General Information

- Belt Specification

- Urethane Specification & Tolerances

- Ordering Information

Urethane has become a workhorse in countless production situations around the world. Why? It is tough, can be made to any length, and stands up to the harshest industrial and environmental conditions. That makes it an outstanding value. Ask us about it.

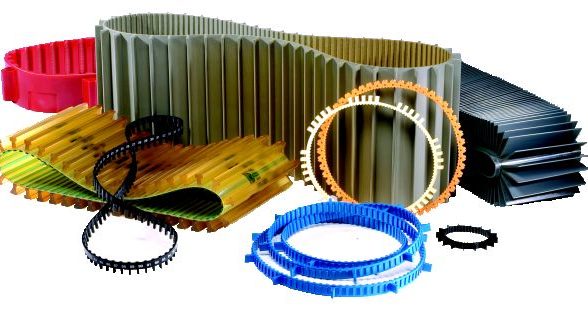

- Available Pitch Sizes:

XL, L, H, XH

T5, T10, T20, AT5, AT10, AT20

HTD®: 5M, 8M,14M - The widest selection available

- Steel and Kevlar® cord construction provides excellent strength

- Cost effective

- Readily available

- Long lengths slit to various widths

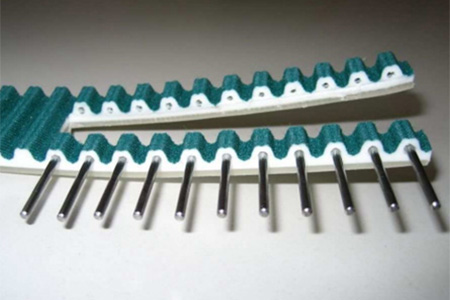

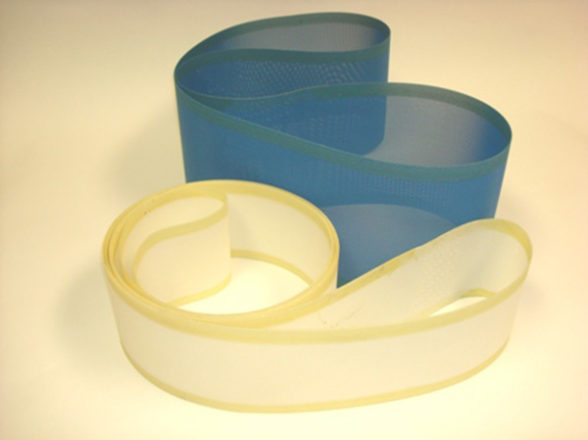

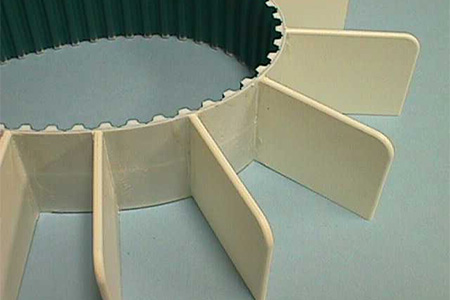

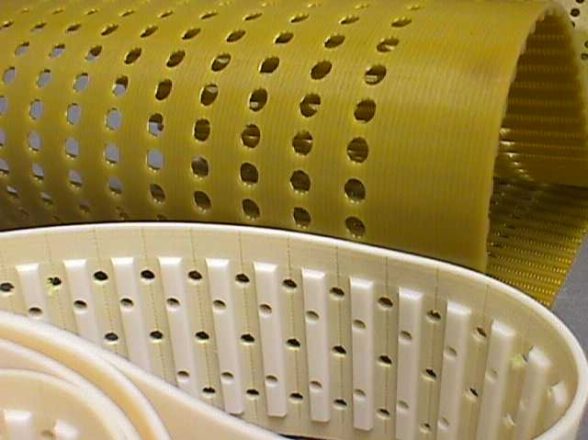

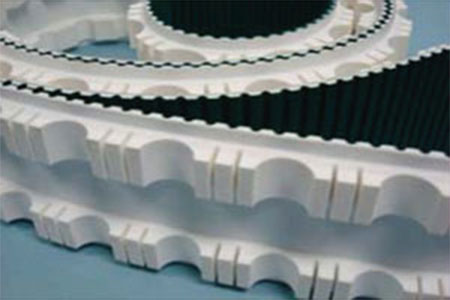

| Urethane Belts | Open-ended roll lengths can be thermally welded to almost any required length, or fixed end to end with our clamping plates. Truly endless is the strongest construction, recommended for drive and high torque applications. |

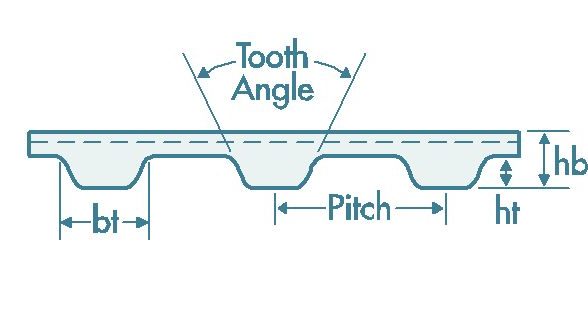

| Urethane Construction and Teeth | Molded integrally the urethane protects the cords and provides a strong, flexible and excellent wear-resistant belt. Various urethane compounds are available depending on construction. To ensure correct engagement with the pulley grooves, the teeth are precisely formed and accurately spaced. They are precisely located so that the tooth root line lies substantially on the pitch line; thus, the tooth spacing of the belt is not altered by flexing. Low friction nylon fabric on the tooth and/or back side, is available on thermal weldable urethane. |

| Tensile Member | The parallel cord tensile member is the secret of the belt’s enormous strength, its excellent flex life, and high resistance to elongation. Various tensile members are available depending on construction and belt pitch, such as Steel, Kevlar® and Polyester. |

| Urethane Characteristics |

|

| Temperature Range | 23 to +158 ºF |

| Standard Durometer | 92 Duro. Shore A 85 Duro. Shore A-FDA |

| Coefficient of Friction | Urethane vs. Steel (dry): 0.5 to 0.7 Urethane vs. UFiMV (dry): 0.2 to 0.4 Nylon vs. Steel (dry): 0.2 to 0.4 Nylon vs. UHMV (dry): 0. 1 to 0.3 |

| Additional Constructions | Hytrel HiTemp Heavy Backing |

| Belt Selections | Belt Selection Range: Steel, Kevlar® – Welded, Open-Ended |

| Belt Sizes | Belt Size Range: XL – STD 8 Pitch Inch Range:0.200” – 0.875” Pitch Metric Range: 5 mm – 20 mm |

| Standard Roll Lengths | Roll Length Range: 100’ – 200’ and 50M – 100M |

For other special constructions and colors contact our Technical Department

| Standard Width | Width Inch Range: ¼” – 18” Width MM Range: 6.35 mm – 457.2 mm |

| Belt Section | Belt Section Range: XL – XH |

| Width Tolerances | Tolerances Range: +0.020 – -0.125” and +0.8 mm – -4.8 mm |

- PHONE: 1-866-672-6339

- EMAIL: beltinfo@fnsheppard.com

Wish to speak with someone right away? Simply call and speak to one of our knowledgeable F.N. Sheppard experts. They will be able to begin engineering a belt that suits your needs quickly and professionally.

NOTE:

All belts are available with Nylon Fabric on either or both sides.

For Nylon on the tooth side, specify “NT”

For Nylon on the back side, specify “NB”

For Nylon on both sides, specify “NTB”

ATI designates stronger cord construction

H-HF & T10-HF designates high flex reinforcement cords

H-XW & T10-XW designates belt width wider than 6″ and up to 18″