Details

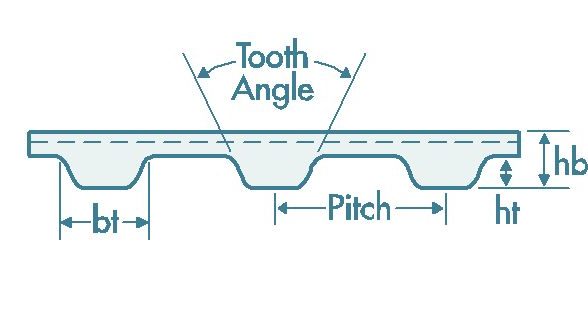

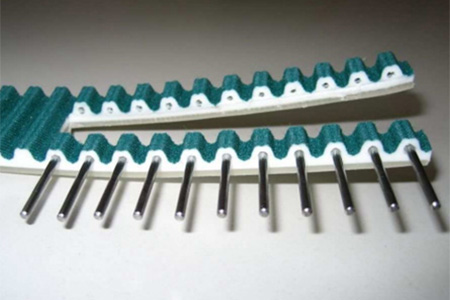

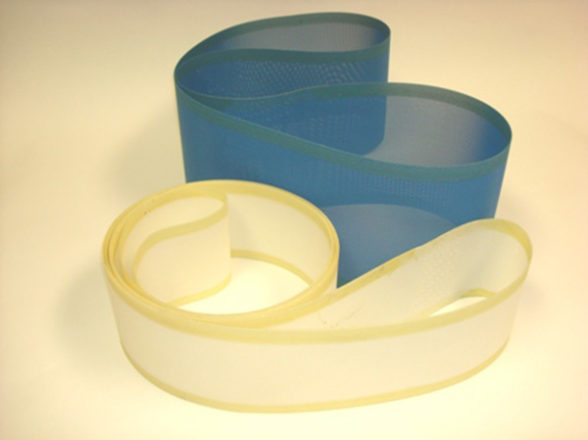

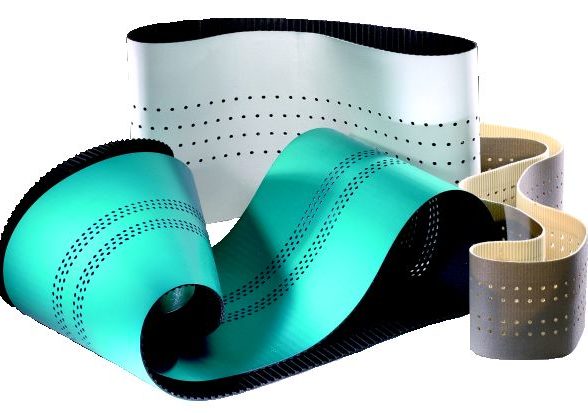

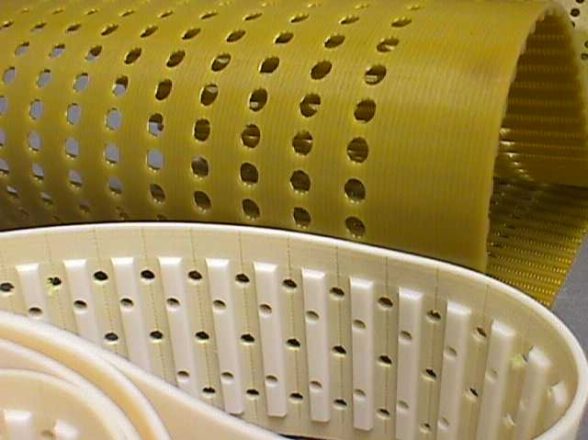

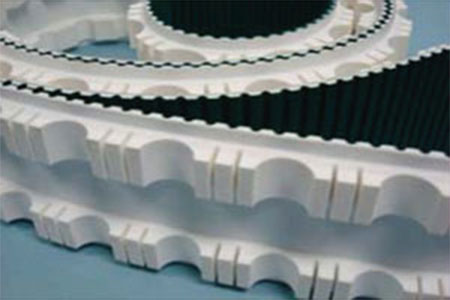

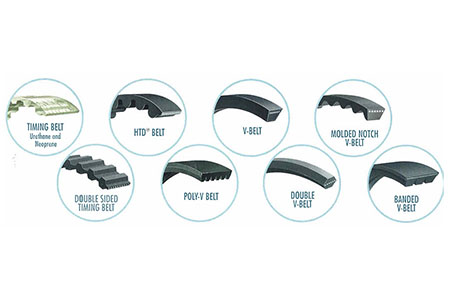

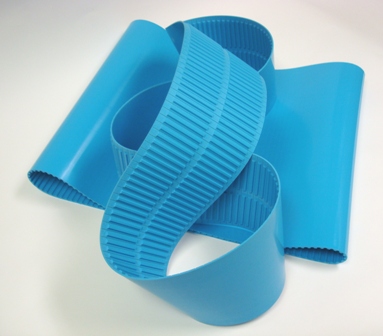

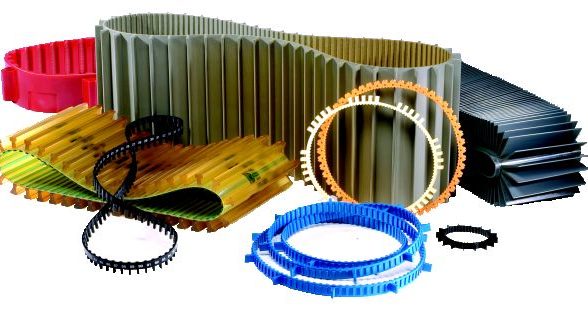

- Category: Timing Belts, Urethane Timing Belts

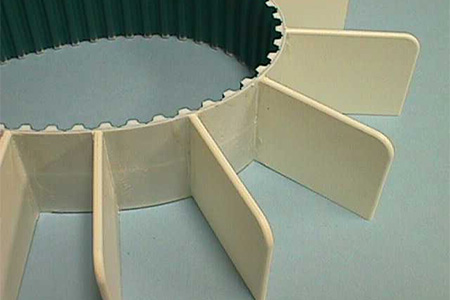

- Timing Center V-guide for Positive Tracking

- Center Tracking without side flanges

- Preferred Tracking for Applications

- Side Loading, Vertical Conveying, Long Transport Belts

Description

Reasons and Applications for Using V-guide Tracking

- For the most positive form of synchronous motion with dynamic true tracking

- Where pulley flanges cannot be used or may interfere with products being conveyed

- Conveyors with long center distance where true tracking is critical

- Side loading or unloading applications

- Where the belt runs on its edge in a vertical position instead of lying flat on a conveyor surface

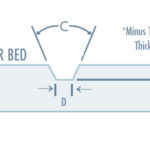

| V-Guide Charts: | Listed are the most common v-guide sizes for urethane timing belts. Dimensions are for integral molded and welded v-guides on urethane timing belts. For other v-guide sizes, material and belt types please contact our technical department. |

| V-Guide Sizes (Inch & Metric): | O, A, B, K6, K8, K10, K13 |

| V-Guide Materials: | FDA, Neoprene, PVC, Urethane |

| V-Guide Construction: | Notched, Serrated, Solid |

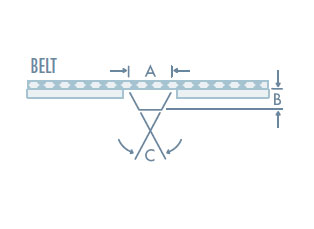

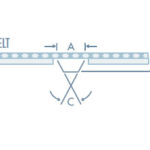

| Urethane V-Guide: Integral Molded & Notched | Belt Tooth Pitch Range: T5 – AT10 V-Section Size Range: K6 – K13 Belt Width Available Range: 16mm – 150mm / 1.5 – 6.0 inch |

| Urethane V-Guide Dimensions | V-Guide Section Range: K6 – A MM Range: 6mm – 13mm Inches Range: 0.240” – 0.500” Pitch Range: 38° – 40° |

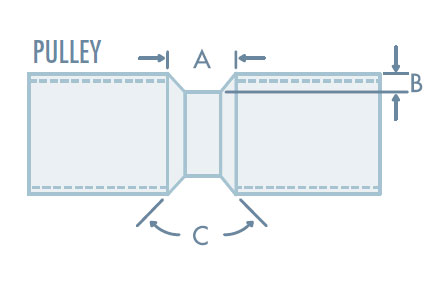

| Pulley Groove Dimensions | V-Guide Section Range: K6 – A MM Range: 5mm – 8.7mm Inches Range: 0.190” – 0.311” Pitch Range: 38° – 44° |

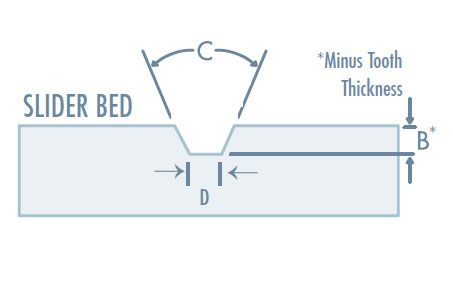

| Slider Bed Dimensions | V-Guide Section Range: K6 – A MM Range: 3.7mm – 8.7mm Inches Range: 0.190” – 0.311” Pitch Range: 38° – 44° |

Below are PDF documents that provide a little more technical information about Self-Tracking Belts. Remember, our business is built on the providing the personal experience for all of our customers, so please, always feel free to give us a call or send us an email at your convenience.

TO PLACE AN ORDER PLEASE CONTACT OUR EXPERIENCED AND PROFESSIONAL CUSTOMER SERVICE TEAM:

- PHONE: 1-866-672-6339

- EMAIL: beltinfo@fnsheppard.com

Wish to speak with someone right away? Simply call and speak to one of our knowledgeable F.N. Sheppard experts. They will be able to begin engineering a belt that suits your needs quickly and professionally.