Details

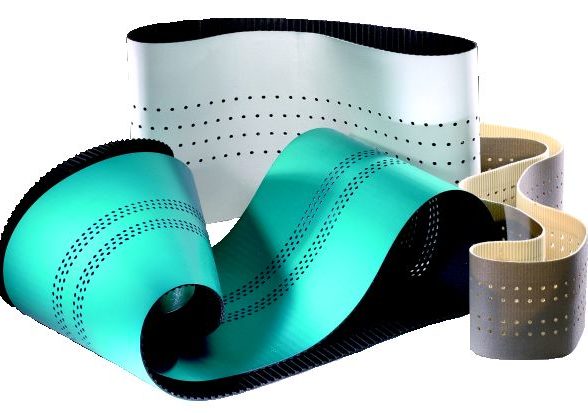

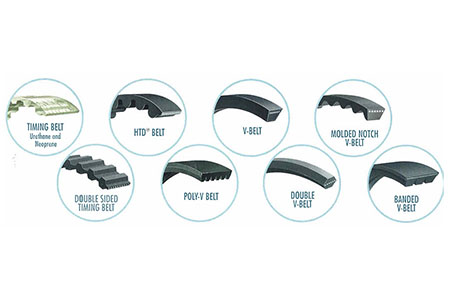

- Category: Timing Belts, Urethane Timing Belts

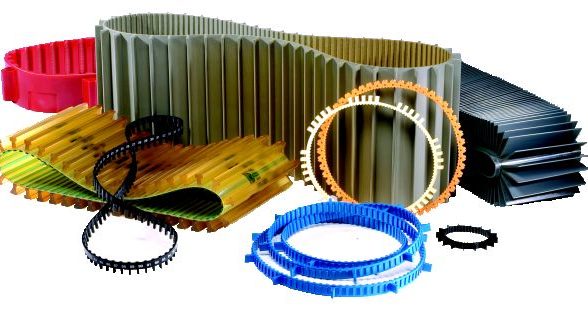

- FDA Food Contact Belts

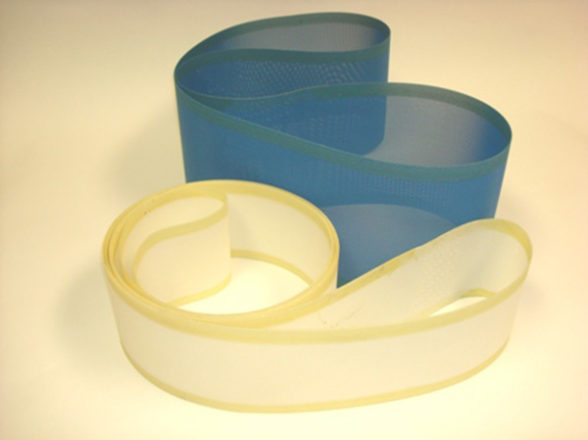

- Typical Colors: Blue, White, Translucent

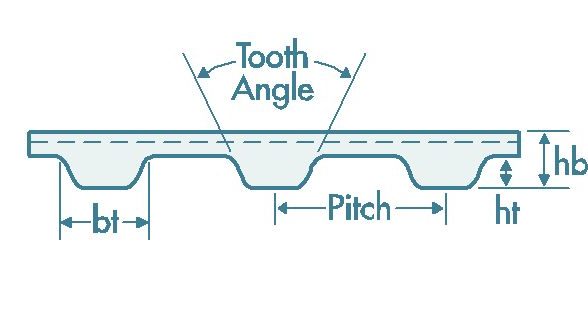

- Many Timing Tooth Pitches, Inch & Metic

- Produced to your requirements

Description

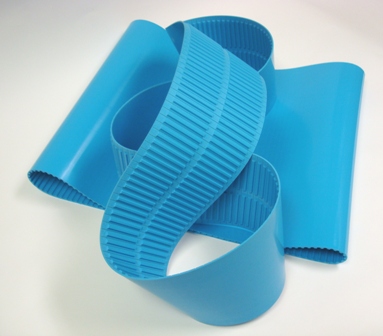

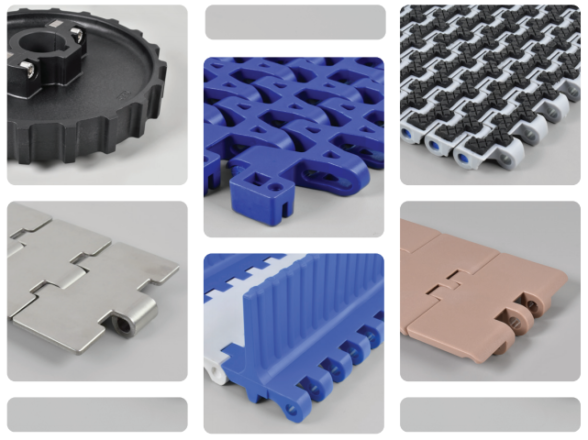

Blue Urethane Timing Belts are popular in food production and packaging applications.

Food safety is the constant goal of the food processing industry. This can only be achieved through implementation of stringent sanitation practices. Selecting belts of a proper construction is a critical component in a total plant hygiene and sanitation strategy. Image, reputation, discriminating consumer tastes and government oversight have combined to create this high-quality standard. Our comprehensive product range offers cost effective conveying solutions in a wide variety of application conditions.

Blue Urethane Timing Belts are popular in food production and packaging applications. Food safety is the constant goal of the food processing industry. This can only be achieved through implementation of stringent sanitation practices. Selecting belts of a proper construction is a critical component in a total plant hygiene and sanitation strategy. Image, reputation, discriminating consumer tastes and government oversight have combined to create this high-quality standard. Our comprehensive product range offers cost effective conveying solutions in a wide variety of application conditions

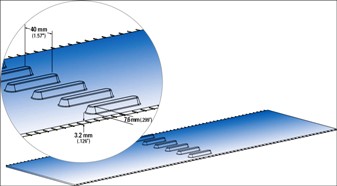

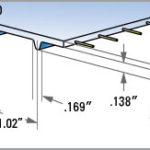

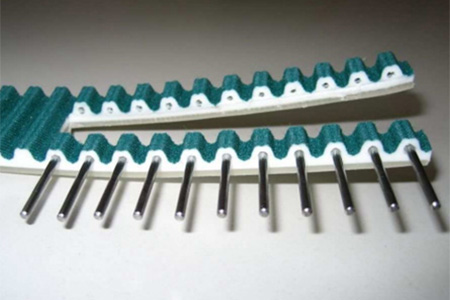

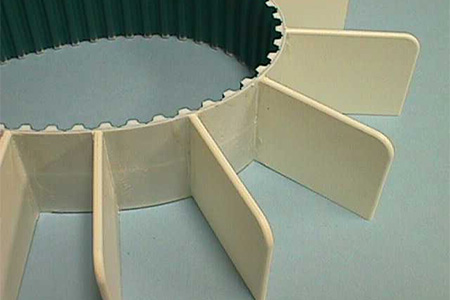

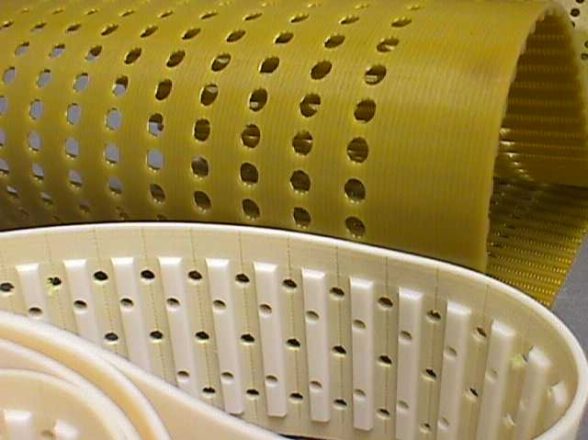

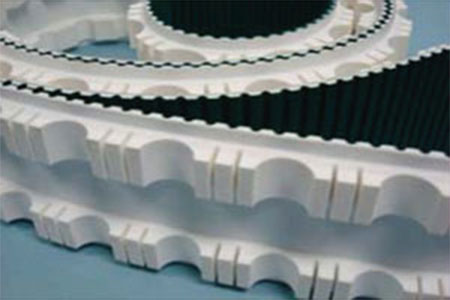

PosiClean® is a line of easy to clean urethane food processing belting designed with sealed Kevlar® tension members and drive teeth across the full belt width. The belt can be cleaned-in-place with resulting savings in water, labor and wastewater disposal when compared to plastic modular belting. The tension members eliminate belt stretch, a common cause of belt failure in long length applications.

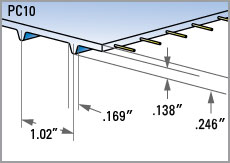

CenterClean™ belts are constructed with flexible urethane and sealed Kevlar® tension members. This construction allows CenterClean™ belts to be troughed or run on small diameter pulley with minimal belt stretch. It is designed for the processing applications requiring synchronous motion. This tooth profile helps to maintain pulley grooves free of debris and easily handles high acceleration and deceleration rates.

- PHONE: 1-866-672-6339

- EMAIL: beltinfo@fnsheppard.com

Wish to speak with someone right away? Simply call and speak to one of our knowledgeable F.N. Sheppard experts. They will be able to begin engineering a belt that suits your needs quickly and professionally.